Customized High Precision Aluminum Timing Belt Pulley

Basic Info

| Place of Origin | China |

| Model Number | Customized |

| Certification | ISO9001:2015 |

| Appliation | Industry, Building, Municipal |

| Min tolerance | +/-0.5mm |

| Samples | We can make sample |

| Sample Time | 20 days |

| Delivery Time | 30~60 days |

| Payment | T/T 30 Days (30% Prepaid) |

WHAT IS A TIMING BELT PULLEY?

A timing belt pulley is a specialized pulley system with teeth or pockets along the outside of the pulley body’s diameter. Like traditional pulley systems, timing belt pulleys are driven by frictional forces between the belt and pulley surfaces. The teeth or pockets on the outside of the pulley are not used for power transmission. Rather, they engage the pulley belt, assisting with timing and averting misalignment.

Pulleys are one of the most common pieces of equipment found in applications around the workplace and in the home. Both your hotel elevator and sewing machine utilize various pulleys to complete necessary functions. Due to the assortment of needs, multiple pulley variations have been created and manufactured according to each application.

Timing belt pulleys are one of the most popular pulleys on the market, known for the unique ability to prevent misalignment and maintain accurate timing during operation.

TIMING BELT PULLEYS

Prized for their reliability, these pulleys are known for minimal operation issues and strictly maintained system timing. Furthermore, unlike many pulleys, belts and gears do not come in direct surface-to-surface contact, eliminating the need for constant lubrication. Finally, Timing Belt Pulleys drastically reduce operation noise as opposed to chains or gears.

Aluminum Timing Belt Pulleys

Specific environmental conditions will play into the selection of pulley materials, the most common being aluminum, steel, and plastic. Each material best fits various environmental conditions and system requirements.

Aluminum is one of the most frequently utilized materials in pulley fabrication. Aluminum is light and durable, excellent for high horsepower drive systems. The tensile strength and durability of aluminum allow for high load capacity while preventing deformation during use. Furthermore, aluminum is often utilized in extreme temperatures, especially intense heat.

Our goal is to provide the finest quality products to our customers efficiently and economically.

Product Description

| Machining Process | Brass Forging and Machining, Precision Machining and Large Machining, Investment Casting of Lost Wax, Pressure Die |

| Surface treatment | Black Oxide, anodic oxidation |

| Material | Aluminum, Steel, Carbon Steel, Stainless Steel, Copper, G25, G3000, Plastic, Nylon |

| Bore Type | Pilot bore, Taper bore and Customized bore |

| Teeth number | 18, 20, 22, 24, 26, 28, 30, 32, 34, 36, 38, 40, 42, 44, 46, 48, 50, 52, 54, 56, 58, 60, 64, 72. |

| Surface treatment | Anodized, Black Oxide, Galvanized, Phospharing |

| Feature | Oil-Resistant, Corrosion-Resistant, Heat-Resistant, Wear-Resistant, Acid-Resistant, High Temperature-Resistance |

| Application | Our products are widely used in many industries, such as agricultural machinery, mining machinery, petroleum machinery, textile machinery, conveyer equipment, packaging machinery, food machinery, engineering machinery, fitness equipment, automobile, truck, train, railway, and other power equipment. |

| Design | Pro/E, Auto CAD, Solid work, CAXA UG, CAM, CAE.Various type of 2D or 3D drawings are acceptable,such as JPG, PDF, DWG, DXF, IGS, STP, X_T, SLDPRT etc. |

| Standards | AISI, ATSM, UNI, BS, DIN, JIS, GB etc.Or Non standard customization. |

| Inspection | 100% inspection on critical dimensions or follow your special requst. |

| Certification | ISO9001:2015 quality management system certificate.( Continuous update ) |

| Equipment | Hobbing machine, Drilling machine, CNC machine, Milling machine, Gear shaper, Grinder etc. |

Features

1.Material: Aluminum, Steel C45, Nylon, etc.

2.Finishing: Black Oxide, Phosphating, Anodizing, Nickel-plated, Zinc-plated etc.

3.Teeth profile: H, XH, XXH; L, XL, MXL; T2.5, T5, T10, T20;HTD / STD 3M, 5M, 8M,14M; AT5, AT10, AT20; 3MR, 5MR; S5M, S8M; RPP5, RPP8 etc.

4.Bore: Pilot bore, Taper bore and Customized bore.

5.Equipment: Hobbing machine, Drilling machine, Machine center, CNC machine, Milling machine, Gear shaper, Grinder etc.

6.Tolerance: As per customer's requirement.

7.OEM and ODM orders are also welcome.

Applications

Conveyor: Belt conveyor, AFC conveyor, Chain conveyor, Screw conveyor.

Pump: Water pump, oil pump, slush pump, etc

Fan: Draft fan, fanner, boiler fan, etc

Excavator: Bucket excavator, Bucket wheel excavators, Bucket wheel stacker reclaimer.

Crane: Tower crane, Gantry crane, Bridge crane.

Others: Various elevators, Coal plough, Ball mill, Crusher, Recreation machine, Blender equipment, Centrifuger, Washer, Leather-making machine, machine for recreation park, mixer wire drawing machine, Extruder,dregs crusher of boiler, Plastic feeder, Rubber smelling machine, etc.

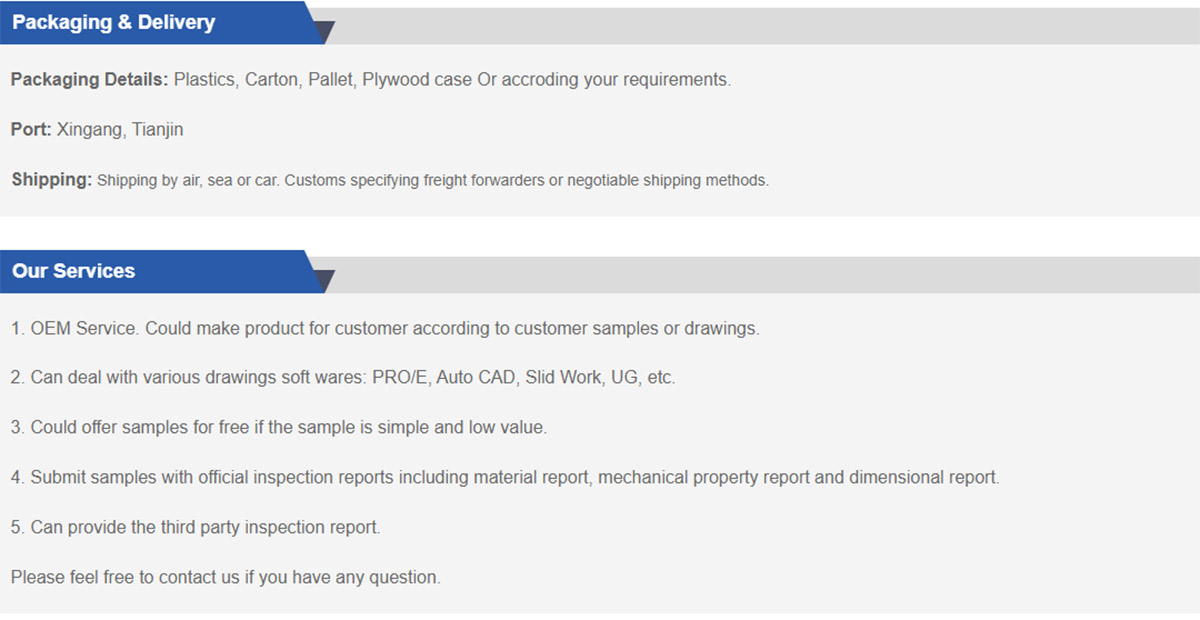

Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.