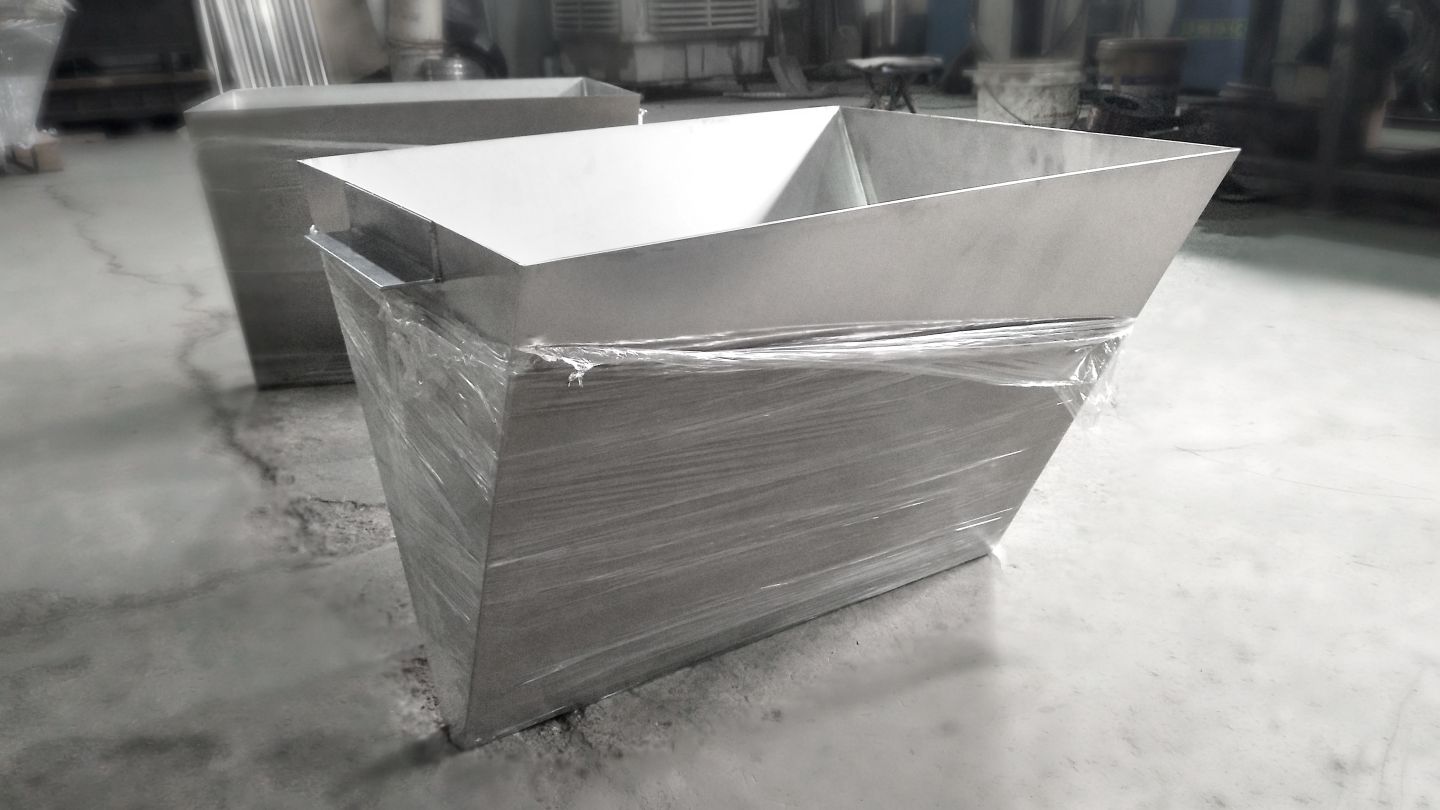

Customized Precision Stainless Steel Sheet Metal Fabrication

Basic Info

|

Place of Origin |

China |

|

Model Number |

Customized |

|

Certification |

ISO9001:2015 |

|

Appliation |

Industry, Building, Municipal |

|

Specification |

According to customer's drawing or sample. |

|

Surface treatment |

Customized |

|

Min tolerance |

+/-0.5mm (According to Drawing) |

|

Samples |

We can make sample |

|

Shipping Port |

Xingang, Tianjin |

|

Delivery Time |

Subject to negotiation date |

|

Payment |

T/T 30 Days (30% Prepaid) |

Fabrication

Stainless Steel Sheet Metal Fabrication

Sheet metal manufacturing is one of the most common types of industrial work, and stainless steel sheet metal is one of the materials of choice for many industries.

From enormous structural projects and construction equipment to intricate telecommunications and electronics, the fabrication of stainless steel is an essential part of projects both large and small.

What is sheet metal fabrication?

One of the most common industrial alloys, stainless steel is highly machinable and adaptable to custom applications. The types of processes, transformations, and finishes it undergoes are as varied and unique as its applications.

Stainless steel fabricators can transform sheet metal with processes such as:

● Bending

● Cutting

● Press and roll forming

● Joining

● Folding

● Mechanical working

● Annealing

● Drawing

● Anodizing

● Electrical discharge machining

● Welding

● Riveting

● Brazing

● Stamping

● Punching

Once a sheet of metal has been transformed into a three-dimensional piece, it can be finished with paint, powder coatings, silk screening, and other specialized surface treatments. Most specialty manufacturers will offer a full array of processing services, all with their own process qualities, finishing options, and unique results.

Stainless Steel Sheet Metal

One of the most widely known steel alloys, stainless steel is also known as inox steel or inox. It is always made up of a minimum of 10.5% chromium, which gives it a number of specific properties.

Unlike standard steel, stainless does not easily rust, corrode, or otherwise stain with water. Different surface finishes and varying grades are increasingly corrosion resistant, and some will perform better than others when exposed to high-salinity, low air circulation, and other such demanding environments.

Stainless steel fabricators will often stock a variety of choices in sheet form. These may include various finishes, sizes, thicknesses, and grades of the following types:

Austenitic, 200 series — Combined with the 300 series, this alloy comprises over 70% of stainless steel manufacturing. A blend of carbon, chromium, nickel, and/or manganese, this steel can be hardened through cold working but is weaker in corrosion resistance.

Austenitic, 300 series — The most widely used austenite steel is grade 304, also known as A2 stainless or 18/8 for its 18% chromium and 8% nickel content. 316, the second most common grade, qualifies as marine grade and can commonly be found in high quality cookware and cutlery.

Ferritic — This stainless steel metal sheet has superior engineering properties but reduced corrosion as compared to austenitic alloys. Lower chromium and nickel content, as well as the occasional inclusion of lead, make it less costly. Some can be enhanced with aluminum or titanium, as well.

Martensitic — Not as corrosion resistant as austenitic or ferritic stainless steel sheeting, martensitic makes up for the shortcoming with extreme strength and machinability. It contains chromium, molybdenum, nickel, and carbon.

Duplex — Roughly a 50/50 mix of austenite and ferrite, duplex stainless steel has an overall lower alloy content than comparable austenitic grades, which makes it popular for many applications due to its economical price point. It’s also twice as strong as austenitic stainless and contains high chromium and low nickel proportions, making it more resistant to corrosion, cracking, and pitting.

Precipitation-hardening martensitic — With better corrosion resistance than standard martensitic steels, this metal can also be precipitation hardened for higher strength applications.

Sheet metal fabrication first involves carefully choosing the right material, supported by a combination of manufacturing processes and finishing.

Product Description

|

Process |

Machining + Surface treatment ( We can provide a whole product line. ) |

|

Machining |

Drilling, Reaming and Tapping CNC Machining: CNC Turning machining, CNC Milling machining, CNC Grinding Laser cutting, welding, bending, Wire EDM, punching, etc. |

|

Surface treatment |

- Passivation - Polishing - Sand blasting - Electroplating(color, blue, white, black zinc, Ni, Cr, tin, copper, silver) - Hot-dip galvanizing - Black oxide coating - Spray-Paint - Rust preventive oil |

|

Processing Ability |

Size tolerance: +/-0.5mm or Accroding to drawings |

|

Material |

Stainless Steel |

|

Application |

Our products are widely used in Industrial , Building & Municipal. Such as automobile, truck, train, railway, fitness equipment, agricultural machinery, mining machinery, petroleum machinery, engineering machinery, shipbuilding, construction and other power equipment.

Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts |

|

Design |

Pro/E, Auto CAD, Solid work, CAXA UG, CAM, CAE. Various type of 2D or 3D drawings are acceptable,such as JPG, PDF, DWG, DXF, IGS, STP, X_T, SLDPRT etc. |

|

Standards |

AISI, ATSM, UNI, BS, DIN, JIS, GB etc. Or Non standard customization. |

|

Inspection |

Dimension inspection Finish inspection Material inspection - ( Inspection on critical dimensions or follow your special requst. ) |

|

Equipment |

CNC Milling Machines,CNC Turning Mashines, Cutting Machines, Polishing Machines, Bending Machines, Electric Welding Machine, Screw Machines, Etc |

|

Certification |

ISO9001:2015 quality management system certificate. ( Continuous update ) |

Custom Sheet Metal Fabrication

Precision sheet metal fabrication is one of the most necessary types of modern industrial manufacturing. Our team of expert craftsmen are skilled in a wide array of sheet metal fabricating processes, and we’re proud to take your project specifications and deliver high quality precision metal products.

Sheet Metal Fabrication Services

● Automated Laser Cutting

● Automated Brake Forming

● Press Brake Forming

● Punching

● Turret Press Fabrication

● Automated Robotic Welding

● Machining Centers

● Tooling and Finishing Services

Our state-of-the-art systems offer complete, high quality custom production, assembly, and finishing services, no matter how complicated your project may be.

Industries and Specialties

Sheet metal fabrication serves industries of all kinds. Raw metal material is transformed into specialized components large and small, from intricate electronic enclosures and chassis to high-performance sealed metal shipping containers.

We provide top services for a broad range of discerning industries, including:

● Defense/Military

● Medical

● Aerospace/Avionics

● Energy

● Electronic enclosures

● Custom projects

Custom Work and Certifications

We are committed to providing quality precision metal fabrication and manufactured parts that strictly conform to your design requirements and specifications.

● We handle a variety of materials, including cold rolled steel, stainless steel, aluminum, and more.

● Our custom parts are manufactured to very tight tolerances.

● As a full service manufacturer, we can handle a wide array of metal fabrication projects from start to finish.

● We have the unique ability to provide in-house finishing services for a wide array of painting processes, including powder coat, CARC, and silk screening.

● Our facilities are equipped with advanced equipment, computer shop floor systems, and engineering systems, with capabilities for handling both small and large production runs.

● We offers top welding services, with multiple Certified Welders to consistently and rapidly produce perfect welds.

100% Quality, 100% Delivery

We know that great precision sheet metal fabrication is about more than manufacturing, and we take pride in constantly improving our customer experience, technology, and support. We work closely with our customers in order to provide the highest level of service.

We combine our vast knowledge and expertise with state-of-the-art equipment and software to produce work quickly, efficiently, and at competitive prices. Precision Metal Industries exceeds ISO 9001:2015 requirements and we constantly review and improve our procedures for better results.

Our facilities are fully equipped with a wide array of sheet metal fabrication equipment, and can take your projects start to finish with unique in-house finishing services for many paint processes.

Factory