Factory Price 1-3500 Mesh Square Stainless Steel Wire Mesh

Basic Info

| Model NO. | weiyue filter mesh |

| Wire Mesh Width | 0.5m,1m, 1.2m, 1.5m Ect |

| Technique | Woven |

| Nickels | 0%~10% |

| Certification | ISO9001 |

| Length of Roll | 50m |

| Others | According to Your Requirement |

| Diameter | 0.02-2.0mm |

| Roll Size | 1*15m, 1*30m |

| Mesh | 1-200 |

| Wire Grade | 302 304 304L 316 316L etc |

| Transport Package | Carton or Wooden Box |

| Specification | 4mesh, 6mesh, 8mesh, 100mesh, 400mesh. |

| Origin | China |

| HS Code | 73144000 |

| Production Capacity | 1000m2 Per Day |

Product Description

We manufactures custom high-performance filters and filtration products for all industries such as wire mesh filters, wire cloth filters, and material-specific filters like stainless steel mesh filters. Using our high-quality wire cloth, welded wire mesh, annealed and diffusion bonded wire mesh; we offer stamping, fabricating and finishing services to manufacture production-ready filters for your applications.

Plain Weave Stainless Steel Wire Mesh Cloth for Filter - Most Common Type

Plain weave stainless steel wire mesh is made of a weft wire and a warp wire with same diameter woven together. Each warp wire crosses alternately above and below every weft wire and vice versa, forming a rectangle or square opening.

With good resistance to corrosion and abrasion, stainless steel wire cloth can be made into filter in petroleum, chemical fiber, food processing, electroplating industries, etc. And it is also used for window screen or decoration.

Specifications of plain weave stainless steel wire mesh:

Materials: stainless steel 302, 304, 304L, 310, 316, 316L, 321, 410, 410L, super duplex stainless steel, duplex stainless steel or customized.

Mesh patterns: square, rectangle.

Surface treatment: pickling and passivation, polishing.

Packing:

Rolls wrapped with craft paper and then put into carton or on pallet;

Sheets in wooden boxes or on pallets.

| Specifications of Plain Weave Stainless Steel Wire Mesh | |||

| Mesh | Wire Diameter (mm) | Opening (mm) | Weight (kg/m2) |

| 1 | 2 | 23.4 | 2.0 |

| 2 | 1.5 | 11.2 | 2.25 |

| 3 | 1.0 | 7.466 | 1.5 |

| 4 | 0.9 | 5.45 | 1.62 |

| 5 | 0.8 | 4.28 | 1.6 |

| 6 | 0.7 | 3.53 | 1.47 |

| 7 | 0.6 | 3.02 | 1.26 |

| 8 | 0.5 | 2.675 | 1.0 |

| 9 | 0.5 | 2.322 | 1.125 |

| 10 | 0.8 | 1.74 | 3.2 |

| 11 | 0.7 | 1.609 | 2.695 |

| 12 | 0.6 | 1.516 | 2.16 |

| 13 | 0.5 | 1.453 | 1.625 |

| 14 | 0.4 | 1.414 | 1.12 |

| 15 | 0.4 | 1.293 | 1.2 |

| 16 | 0.35 | 1.237 | 0.98 |

| 17 | 0.35 | 1.144 | 1.041 |

| 18 | 0.35 | 1.061 | 1.10 |

| 19 | 0.35 | 0.986 | 1.16 |

| 20 | 0.4 | 0.97 | 0.97 |

| 21 | 0.3 | 0.909 | 0.945 |

| 22 | 0.3 | 0.854 | 0.99 |

| 23 | 0.25 | 0.854 | 0.718 |

| 24 | 0.25 | 0.858 | 0.48 |

| 25 | 0.2 | 0.816 | 0.50 |

| 26 | 0.2 | 0.076 | 0.52 |

| 27 | 0.2 | 0.740 | 0.54 |

| 28 | 0.3 | 0.607 | 1.26 |

| 29 | 0.3 | 0.575 | 1.30 |

| 30 | 0.3 | 0.546 | 1.35 |

| 40 | 0.25 | 0.385 | 1.25 |

| 50 | 0.2 | 0.308 | 1.0 |

| 60 | 0.15 | 0.273 | 0.675 |

| 70 | 0.14 | 0.222 | 0.686 |

| 80 | 0.12 | 0.197 | 0.576 |

| 90 | 0.11 | 0.172 | 0.544 |

| 100 | 0.10 | 0.154 | 0.50 |

| 120 | 0.08 | 0.131 | 0.384 |

| 150 | 0.07 | 0.099 | 0.367 |

| 380 | 0.02 | 0.046 | 0.076 |

| 400 | 0.018 | 0.0455 | 0.0648 |

Plain weave stainless steel wire mesh features:

The most common type;

Good resistance to acid and alkali, and corrosion;

Abrasion, high temperature resistant;

Durable and high strength;

Easy to clean and maintain;

Flat and shiny surface.

Plain weave stainless steel wire mesh applications:

Used for filter or sieve in mining, chemical fiber, pharmaceutical industries, such as mud mesh, pickling mesh;

Made into window screen, fruit basket, infill panel, etc

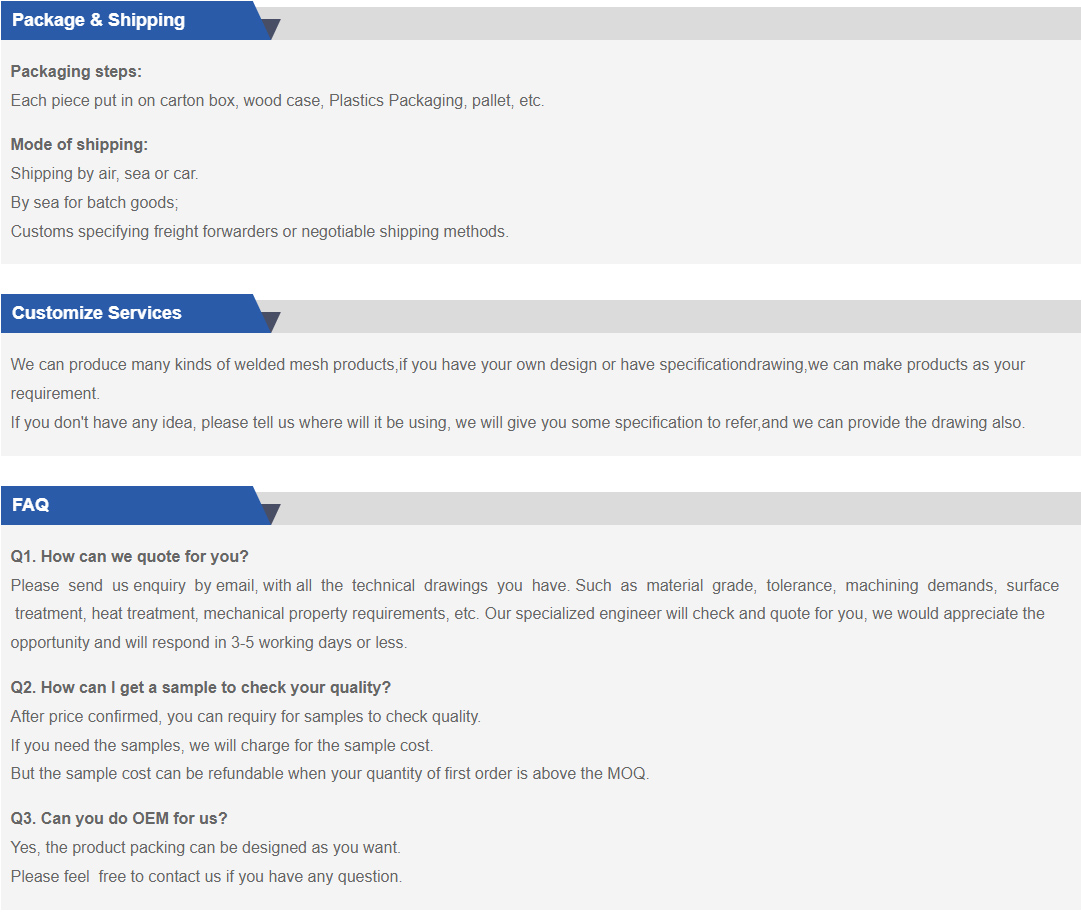

Twill Weave Stainless Steel Wire Mesh for Screen, Mud or Pickling Mesh

Twill weave stainless steel wire mesh possesses the processing that each weft wire passes over and under two warp wires and vice versa, forming a beautiful appearance. And the wire diameter for warp wire and weft wire is mostly the same.

Twill weave stainless steel wire cloth resists to acid, alkali, high temperature and is durable and solid. It can be used for strainer screen to filter liquid, gas, solid in various industries. Of course, it also can be designed into infill panel, fruit and vegetable basket, etc.

Specifications of twill weave stainless steel wire mesh:

Materials: 302, 304, 304L, 310, 316, 316L, 321, 410, 410L, 430, 904L, super duplex stainless steel, duplex stainless steel or customized.

Width: 0.5-1.5 m.

Roll length: 30 m a roll or customized.

Surface treatment: pickling and passivation, polishing.

Packing:

Rolls wrapped with craft paper and then put into carton or on pallet;

Sheets in wooden boxes or on pallets.

| Specifications of Twill Weave SS Wire Mesh | ||||

| Items | Mesh | Wire Diameter (mm) | Mesh Aperture (mm) | Material (AISI) |

| SSTW01 | 250 × 250 | 0.040 | 0.063 | SUS316 |

| SSTW02 | 300 × 300 | 0.040 | 0.044 | |

| SSTW03 | 325 × 325 | 0.035 | 0.043 | SUS316L |

| SSTW04 | 350 × 350 | 0.030 | 0.042 | |

| SSTW05 | 400 × 400 | 0.030 | 0.033 | |

| SSTW06 | 450 × 450 | 0.028 | 0.028 | |

| SSTW07 | 500 × 500 | 0.025 | 0.026 | |

Twill weave stainless steel wire mesh features:

Excellent resistance to the rust and corrosion;

Resist to the chemical and harsh weather;

Accurate filtration rating;

Durable and has high friction coefficient;

High strength and beautiful appearance.

Twill weave stainless steel wire mesh applications:

Sieve or filter liquid, gas, solid;

Used in oil, chemical fiber, plating industries or medical equipment, food processing;

Made into infill panel, vegetable basket, decoration.

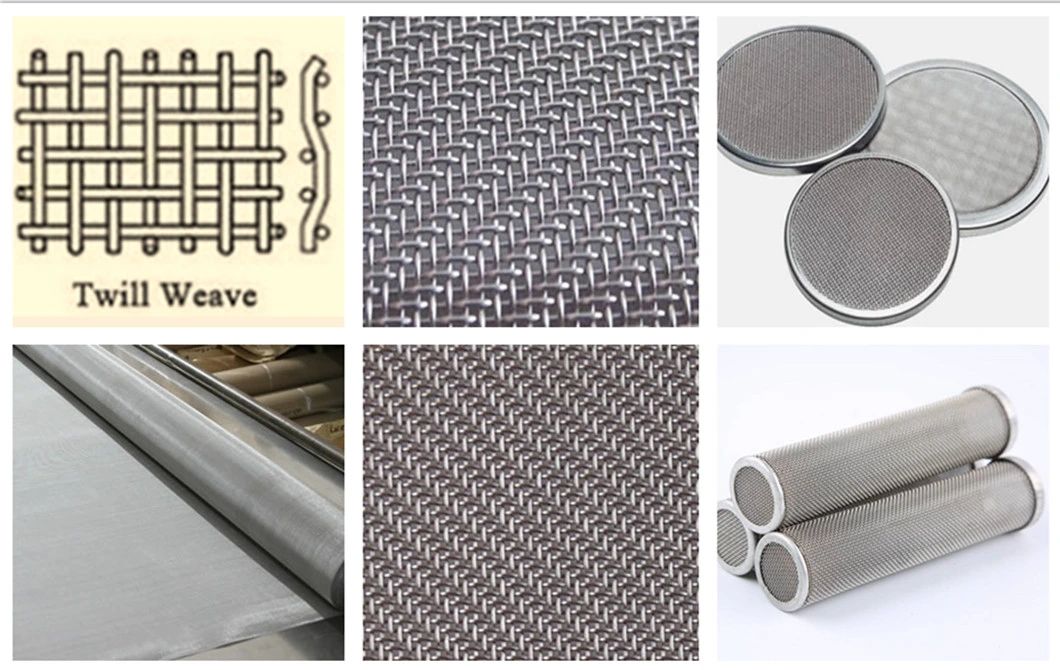

Stainbless Steel Dutch Wire Mesh Used in Fuel Filter, Aerospace, Rubber Industry

Stainless Steel Dutch Wire Mesh has different warp and weft wire numbers and diameter: more weft numbers and thicker warp wire. And it is classified into plain dutch weave and twill dutch weave.

With high filter precision, dutch weave ss wire mesh can sieve and filter solid, liquid, gas in corrosive environment. And it has great strength and is used in petroleum, aerospace, chemical, medicine, food or water treatment industries.

Specifications of stainless steel dutch wire mesh:

Materials: stainless steel 202, 302, 304, 304L, 310S, 316, 316L, 321, 410, 430, super duplex stainless steel, duplex stainless steel, etc.

Weaving method: plain dutch weave, twill dutch weave.

Surface treatment: pickling and passivation, polishing.

Packing:

Rolls wrapped with craft paper and then put into carton or on pallet;

Sheets in wooden boxes or on pallets.

| Specifications of Stainless Steel Plain Dutch Wire Mesh | |||||

| Mesh/Inch (warp×weft) | Wire Dia. warp×weft (mm) | Normal size (μm) | Effective area% |

Weight kg/sq.m | Cloth thickness (mm) |

| 7×44 | 0.71×0.63 | 319 | 14.2 | 5.55 | 1.97 |

| 8×45 | 0.8×0.6 | 310 | 15.5 | 5.7 | 2.00 |

| 8×60 | 0.63×0.45 | 296 | 20.3 | 4.16 | 1.53 |

| 8×85 | 0.45×0.315 | 275 | 27.3 | 2.73 | 1.08 |

| 10×90 | 0.45×0.28 | 249 | 29.2 | 2.57 | 1.01 |

| 10×76 | 0.5×0.355 | 248 | 21.8 | 3.24 | 1.21 |

| 12×86 | 0.45×0.315 | 211 | 20.9 | 2.93 | 1.08 |

| 12×64 | 0.56×0.40 | 211 | 16.0 | 3.89 | 1.36 |

| 12×76 | 0.45×0.355 | 192 | 15.9 | 3.26 | 1.16 |

| 14×100 | 0.40×0.28 | 182 | 20.3 | 2.62 | 0.96 |

| 14×110 | 0.4×0.25 | 177 | 22.2 | 2.28 | 0.855 |

| 14×76 | 0.45×0.355 | 173 | 14.3 | 3.33 | 1.16 |

| 16×100 | 0.40×0.28 | 160 | 17.7 | 2.7 | 0.96 |

| 17×120 | 0.355×0.224 | 155 | 22.4 | 2.19 | 0.803 |

| 16×120 | 0.28×0.224 | 145 | 19.2 | 1.97 | 0.728 |

| 20×140 | 0.315×0.20 | 133 | 21.5 | 1.97 | 0.715 |

| 20×170 | 0.25×0.16 | 130 | 28.9 | 1.56 | 0.57 |

| 20×110 | 0.355×0.25 | 126 | 15.3 | 2.47 | 0.855 |

| 22×120 | 0.315×0.224 | 115 | 15.5 | 2.20 | 0.763 |

| 25×140 | 0.28×0.20 | 100 | 15.2 | 1.96 | 0.68 |

| 24×110 | 0.355×0.25 | 97 | 11.3 | 2.60 | 0.855 |

| 28×150 | 0.28×0.18 | 92 | 15.9 | 1.87 | 0.64 |

| 30×150 | 0.25×0.18 | 82 | 13.5 | 1.79 | 0.61 |

| 30×140 | 0.315×0.20 | 77 | 11.4 | 2.21 | 0.715 |

| 35×190 | 0.224×0.14 | 74 | 16.8 | 1.47 | 0.504 |

| 35×170 | 0.224×0.16 | 69 | 12.8 | 1.62 | 0.544 |

| 40×200 | 0.18×0.135 | 63 | 15.4 | 1.24 | 0.43 |

| 50×250 | 0.14×0.11 | 50 | 15.2 | 1 | 0.36 |

| 60×500 | 0.14×0.055 | 51 | 34.1 | 0.70 | 0.252 |

| 50×270 | 0.14×0.10 | 50 | 15.2 | 0.98 | 0.34 |

| 65×390 | 0.125×0.071 | 42 | 19.1 | 0.78 | 0.267 |

| 60×300 | 0.14×0.09 | 41 | 14.1 | 0.96 | 0.32 |

| 80×700 | 0.125×0.04 | 40 | 38.1 | 0.60 | 0.205 |

| 60×270 | 0.14×0.10 | 39 | 11.2 | 1.03 | 0.34 |

| 77×560 | 0.14×0.05 | 38 | 27.5 | 0.74 | 0.24 |

| 70×390 | 0.112×0.071 | 37 | 16.3 | 0.74 | 0.254 |

| 65×750 | 0.10×0.036 | 36 | 37.1 | 0.43 | 0.172 |

| 70×340 | 0.125×0.08 | 35 | 13.2 | 0.86 | 0.285 |

| 80×430 | 0.125×0.063 | 32 | 16.6 | 0.77 | 0.251 |

| 118×750 | 0.063×0.036 | 23 | 21.5 | 0.38 | 0.135 |

| Specifications of Stainless Steel Twill Dutch Wire Mesh | |||

| Weft × Warp (inch) | Aperture Size (μm) | Available Area (%) | Thickness (mm) |

| 20 × 270 | 119 | 17.6 | 0.65 |

| 20 × 200 | 118 | 12.1 | 0.915 |

| 24 × 300 | 110 | 19.6 | 0.64 |

| 20 × 150 | 101 | 7.5 | 1.16 |

| 30 × 340 | 89 | 17.9 | 0.60 |

| 30 × 270 | 77 | 11.2 | 0.68 |

| 40 × 540 | 70 | 23.5 | 0.38 |

| 40 × 430 | 63 | 15.4 | 0.43 |

| 50 × 600 | 51 | 17.2 | 0.305 |

| 50 × 500 | 47 | 12 | 0.364 |

| 65 × 600 | 36 | 12 | 0.32 |

| 70 × 600 | 31 | 10.1 | 0.32 |

| 78 × 760 | 31 | 13.5 | 0.254 |

| 78 × 680 | 29 | 10.3 | 0.272 |

| 80 × 680 | 28 | 9.8 | 0.272 |

| 90 × 850 | 26 | 12.7 | 0.226 |

| 90 × 760 | 24 | 9.6 | 0.242 |

| 100 × 850 | 22 | 10 | 0.226 |

| 130 × 1500 | 21 | 18.6 | 0.135 |

| 100 × 760 | 20 | 7.4 | 0.242 |

| 130 × 1200 | 18 | 12 | 0.161 |

| 130 × 1100 | 17 | 9.4 | 0.171 |

| 150 × 1400 | 15 | 11.4 | 0.143 |

| 160 × 1500 | 15 | 12.4 | 0.135 |

| 165 × 1500 | 14 | 11.4 | 0.135 |

| 174 × 1700 | 13 | 12.9 | 0.127 |

| 165 × 1400 | 13 | 8.8 | 0.143 |

| 174 × 1400 | 11 | 7.4 | 0.143 |

| 203 × 1600 | 10 | 9.3 | 0.114 |

Stainless steel dutch wire mesh features:

Solid and stable structure;

Good resistance to corrosion, abrasion, high temperature;

Resist to acid, alkali, rust;

High filter precision.

Stainless steel dutch wire mesh applications:

Filter or sieve food, medicine, chemical fiber, fuels, powders, etc;

Used for precision pressure filter, fuel filter, vacuum filter;

Used in hydraulic systems, aerospace, water treatment, metallurgy industries.

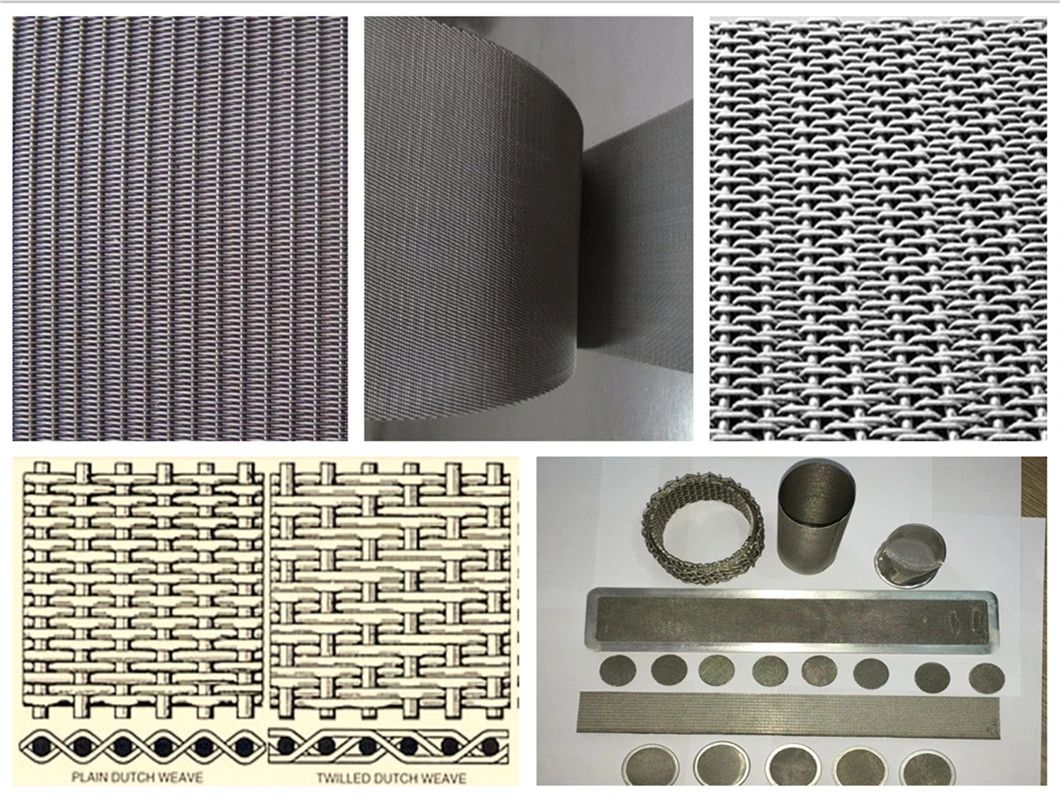

Stainless Steel Reverse Dutch Wire Mesh is Durable and Solid

Stainless Steel reverse dutch wire mesh is a specially designed filter product with different diameter wires: thicker weft than warp. And it has high tensile strength and is more durable and solid than the common weave wire mesh.

Reverse dutch wire mesh is widely used for filter with outstanding filtration performance and rust and corrosion resistance. It also play an important role in machinery, plastic products, chemical fiber, food or medicine industries, etc.

Specifications of stainless steel reverse dutch wire mesh:

Materials: stainless steel 202, 302, 304, 304L, 310S, 316, 316L, 321, 410, 430, super duplex stainless steel, duplex stainless steel, etc.

Surface treatment: pickling and passivation, polishing.

Packing:

Wrapped with moisture-proof paper or plastic paper;

In wooden boxes or pallets.

| Specifications of Stainless Steel Reverse Dutch Wire Mesh | ||

| Mesh (Weft × Warp) | Wire Diameter (mm) | Weight (kg/m2) |

| 72 × 15 | 0.45 × 0.55 | 4.8 |

| 120 × 16 | 0.35 × 0.45 | 4.3 |

| 132 × 18 | 0.35 × 0.45 | 4.3 |

| 152 × 24 | 0.35 × 0.45 | 4.5 |

| 160 × 17 | 0.27 × 0.45 | 3.6 |

| 170 × 17 | 0.27 × 0.45 | 3.89 |

| 180 × 19 | 0.26 × 0.45 | 4.05 |

| 200 × 40 | 0.17 × 0.27 | 2.17 |

| 260 × 40 | 0.15 × 0.25 | 2.09 |

| 325 × 40 | 0.13 × 0.24 | 1.95 |

Stainless steel reverse dutch wire mesh features:

High hardness and tensile strength;

Zero aperture;

Excellent filtration performance;

Good resistance to acid and alkali;

Rust and corrosion resistance;

Beautiful surface.

Stainless steel reverse dutch wire mesh applications:

Used for filter disc, filter tube, fine filter media;

Play a role in chemical, petroleum, plastic products, metallurgy, aerospace, food processing industries.

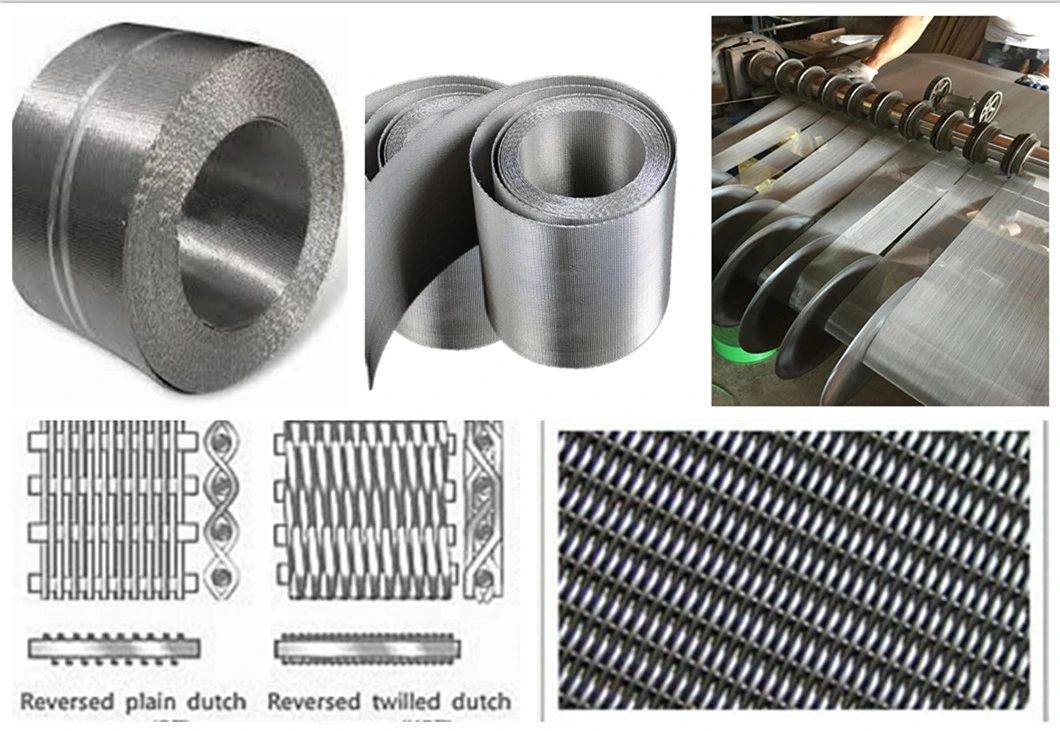

Stainless Steel Crimped Wire Mesh Can Roast Meat, Ensure Safety

Stainless steel crimped wire mesh is crimped before weaving, and it has solid structure, good loading capacity and beautiful appearance.

Crimped wire mesh is widely used for vibrating screen, quarry screen, filter, infill panel, barbecue grill, and shows its ability in chemical, petroleum, mining industries, livestock breeding, etc.

Specifications of stainless steel crimped wire mesh:

Materials: stainless steel 301, 302, 304, 304L, 316, 316L, 321.

Mesh width: up to 2000 mm.

Aperture width: 10-120 mm in the case of multi-notch meshes and 4-40 mm in the case of single-notch meshes.

Weaving method: crimped before weaving.

Surface treatment: pickling and passivation, polishing, galvanized.

Frame:

Cut the edges;

Bent edges;

Sheathed hooks.

Packing:

Sheets on pallets or in wooden cases;

Rolls wrapped with waterproof paper and plastic film.

| Specifications of Stainless Steel Crimped Wire Mesh | ||||

| Wire Gauge SWG |

Wire Diameter mm |

Mesh/Inch | Aperture (mm) |

Weight (kg/m2) |

| 6 | 4.8 | 1 | 20.6 | 11.5 |

| 8 | 4.05 | 2 | 9 | 16.5 |

| 10 | 3.2 | 2 | 10 | 10.5 |

| 12 | 2.6 | 3 | 5.9 | 10.5 |

| 14 | 2.0 | 3 | 6.5 | 6 |

| 16 | 1.6 | 4 | 5 | 5.5 |

| 17 | 1.4 | 5 | 5.1 | 5.0 |

| 18 | 1.2 | 5 | 4 | 3.6 |

| 19 | 1.0 | 6 | 3.2 | 3.0 |

| 21 | 0.8 | 7 | 2.8 | 2.3 |

| 22 | 0.7 | 8 | 2.5 | 2 |

Stainless steel crimped wire mesh features:

High tensile strength and stable structure;

Good resistance to corrosion and abrasion;

Beautiful and shiny surface;

Durable and has good loading capacity.

Stainless steel crimped wire mesh applications:

Used for vibrating screen, test sieve;

Filter and sieve materials in mine, oil refining, construction, chemical industry, food process and other industries;

Made into decorative infill panel, protective mesh, barbecue grill, baking rack.