Stainless Steel Wire Filter Sintered 304 316L Stainless Steel Wire Mesh Filter Layar

Info dhasar

| Jeneng produk | Sintered 304 316L Stainless Steel Wire Mesh Filter |

| Panggunaan | Filtering, Sieving Gunakake |

| Layar Filter | Layar Mesh Filter banyu |

| Pengalaman Pabrik | Luwih saka 10 Taun |

| Teknik | Tenun |

| Jeneng merek | Ruihao |

| Kaluwihan Kita | Produsen Langsung, Stok Cukup |

| Fitur | Tahan Panas, Ramah Lingkungan |

| asale | Hebei |

| Kode HS | 7314140000 |

| Kapasitas Produksi | 100ton / Minggu |

Deskripsi Produk

nepangaken:

Kita nggawe saringan kinerja dhuwur lan produk filtrasi khusus kanggo kabeh industri kayata saringan wire mesh, saringan kain kawat, lan saringan khusus material kaya saringan bolong stainless steel.Nggunakake kain kawat bermutu tinggi, bolong kawat sing dilas, bolong kawat anil lan difusi;kita nawakake layanan stamping, fabrikasi lan finishing kanggo nggawe saringan siap produksi kanggo aplikasi sampeyan.

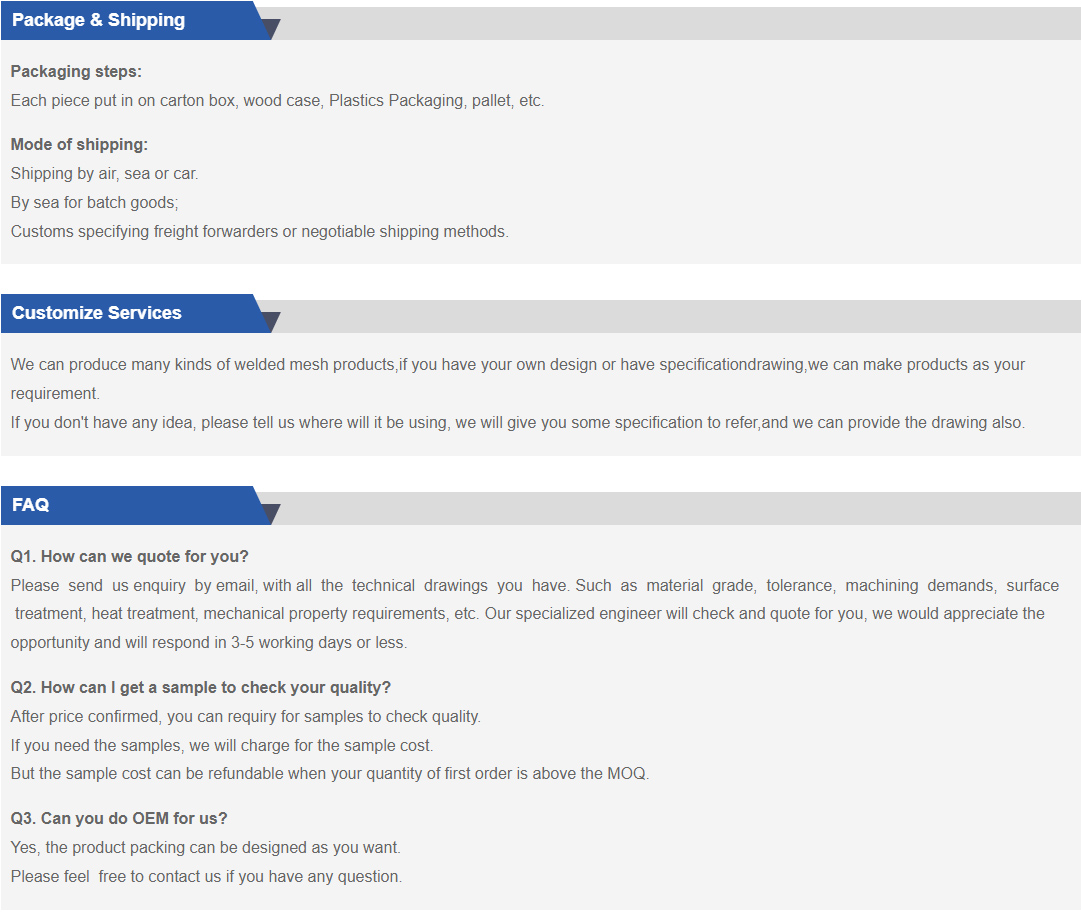

Kain Filter Tenun Polos/Twilled

Loro-lorone weaves iku ekonomi;kanthi tenunan polos sing paling umum lan ekonomi diprodhuksi.Panggunaan wire mesh kalebu: Sizing Partikel misahake lan nyaring Particulate sifting Safety lan peralatan pangayoman.

Tabel ing ngisor iki nuduhake kelas lan spesifikasi standar sing kasedhiya kanggo kain tenun Plain lan Twill.

| Kasedhiya ing Stainless steel 302 304 316 316L | |||||

| Kain Kawat Tenun Polos/Kepar | |||||

| bolong | Gauge | Diameter kawat (mm) | bolong | Gauge | Diameter kawat (mm) |

| 8 | 24 | 0.558 | 30 | 30 | 0.315 |

| 26 | 0.457 | 32 | 0.274 | ||

| 27 | 0.400 | 34 | 0.234 | ||

| 28 | 0.376 | 40 | 32 | 0.274 | |

| 10 | 24 | 0.558 | 33 | 0.254 | |

| 26 | 0.457 | 34 | 0.234 | ||

| 28 | 0.376 | 36 | 0.193 | ||

| 12 | 24 | 0.558 | 37 | 0.173 | |

| 26 | 0.457 | 50 | 34 | 0.234 | |

| 27 | 0.400 | 36 | 0.193 | ||

| 28 | 0.376 | 38 | 0.152 | ||

| 30 | 0.315 | 60 | 34 | 0.234 | |

| 14 | 24 | 0.558 | 38 | 0.152 | |

| 26 | 0.457 | 80 | 38 | 0.152 | |

| 27 | 0.400 | 40 | 0.122 | ||

| 16 | 27 | 0.400 | 42 | 0.102 | |

| 28 | 0.376 | 100 | 41 | 0.112 | |

| 30 | 0.315 | 42 | 0.102 | ||

| 18 | 26 | 0.457 | 43 | 0.091 | |

| 28 | 0.376 | 200 | 47 | 0,051 | |

| 20 | 26 | 0.457 | 300 | 48 | 0.041 |

| 28 | 0.376 | 49 | 0.031 | ||

| 30 | 0.315 | ||||

| 32 | 0.274 | ||||

Kain Filter Tenun Walanda

WEIYUE ngasilake kain kawat khusus kanggo nyukupi kabutuhan filtrasi klien.Bolong panyaring tenunan Walanda nyedhiyakake kemampuan filtrasi sing unggul kanggo macem-macem aplikasi, kalebu saringan tekanan, bahan bakar lan cairan kanggo industri aerospace, petrokimia, farmasi, pertambangan lan perawatan banyu limbah.

Kain Kawat Tenun Walanda Polos

Kain kawat tenunan Walanda polos ditenun nganggo rong ukuran kawat.Kabel sing luwih cilik, cilik kaya ukuran mikron, digunakake ing arah shute lan dirajut nganggo kabel warp sing luwih gedhe.Kabel sing luwih cilik dirajut kanthi rapet, nyedhiyakake bolong sing nyenyet kanggo nyaring.Kawat sing luwih gedhe menehi kekuatan kanggo bolong.Panggunaan utama kain kawat iki yaiku filtrasi lan pamisahan produk cair lan slurry.

Tabel ing ngisor iki nuduhake kelas lan spesifikasi standar sing kasedhiya kanggo Kain Kawat Tenun Walanda

| Mesh/Inci (warp×weft) | Kawat Dia.lungsin × pakan (mm) | Ukuran normal (m) | Efektif | Bobot kg / sq.m | Ketebalan kain |

| 7×44 | 0.71×0.63 | 319 | 14.2 | 5.55 | 1.97 |

| 8×45 | 0.8×0.6 | 310 | 15.5 | 5.7 | 2.00 |

| 8×60 | 0.63×0.45 | 296 | 20.3 | 4.16 | 1.53 |

| 8×85 | 0.45×0.315 | 275 | 27.3 | 2.73 | 1.08 |

| 10×90 | 0.45×0.28 | 249 | 29.2 | 2.57 | 1.01 |

| 10×76 | 0.5×0.355 | 248 | 21.8 | 3.24 | 1.21 |

| 12×86 | 0.45×0.315 | 211 | 20.9 | 2.93 | 1.08 |

| 12×64 | 0.56×0.40 | 211 | 16.0 | 3.89 | 1.36 |

| 12×76 | 0.45×0.355 | 192 | 15.9 | 3.26 | 1.16 |

| 14×100 | 0.40×0.28 | 182 | 20.3 | 2.62 | 0.96 |

| 14×110 | 0.4×0.25 | 177 | 22.2 | 2.28 | 0.855 |

| 14×76 | 0.45×0.355 | 173 | 14.3 | 3.33 | 1.16 |

| 16×100 | 0.40×0.28 | 160 | 17.7 | 2.7 | 0.96 |

| 17×120 | 0.355×0.224 | 155 | 22.4 | 2.19 | 0.803 |

| 16×120 | 0.28×0.224 | 145 | 19.2 | 1.97 | 0.728 |

| 20×140 | 0.315×0.20 | 133 | 21.5 | 1.97 | 0.715 |

| 20×170 | 0.25×0.16 | 130 | 28.9 | 1.56 | 0.57 |

| 20×110 | 0.355×0.25 | 126 | 15.3 | 2.47 | 0.855 |

| 22×120 | 0.315×0.224 | 115 | 15.5 | 2.20 | 0.763 |

| 25×140 | 0.28×0.20 | 100 | 15.2 | 1.96 | 0.68 |

| 24×110 | 0.355×0.25 | 97 | 11.3 | 2.60 | 0.855 |

| 28×150 | 0.28×0.18 | 92 | 15.9 | 1.87 | 0.64 |

| 30×150 | 0.25×0.18 | 82 | 13.5 | 1.79 | 0.61 |

| 30×140 | 0.315×0.20 | 77 | 11.4 | 2.21 | 0.715 |

| 35×190 | 0.224×0.14 | 74 | 16.8 | 1.47 | 0.504 |

| 35×170 | 0.224×0.16 | 69 | 12.8 | 1.62 | 0.544 |

| 40×200 | 0.18×0.135 | 63 | 15.4 | 1.24 | 0.43 |

| 50×250 | 0.14×0.11 | 50 | 15.2 | 1 | 0.36 |

| 60×500 | 0.14×0.055 | 51 | 34.1 | 0.70 | 0.252 |

| 50×270 | 0.14×0.10 | 50 | 15.2 | 0.98 | 0.34 |

| 65×390 | 0.125×0.071 | 42 | 19.1 | 0.78 | 0.267 |

| 60×300 | 0.14×0.09 | 41 | 14.1 | 0.96 | 0.32 |

| 80×700 | 0.125×0.04 | 40 | 38.1 | 1. | 0.205 |

| 60×270 | 0.14×0.10 | 39 | 11.2 | 1.03 | 0.34 |

| 77×560 | 0.14×0.05 | 38 | 27.5 | 0.74 | 0.24 |

| 70×390 | 0.112×0.071 | 37 | 16.3 | 0.74 | 0.254 |

| 65×750 | 0.10×0.036 | 36 | 37.1 | 0.43 | 0.172 |

| 70×340 | 0.125×0.08 | 35 | 13.2 | 0.86 | 0.285 |

| 80×430 | 0.125×0.063 | 32 | 16.6 | 0.77 | 0.251 |

| 118×750 | 0.063×0.036 | 23 | 21.5 | 0.38 | 0.135 |

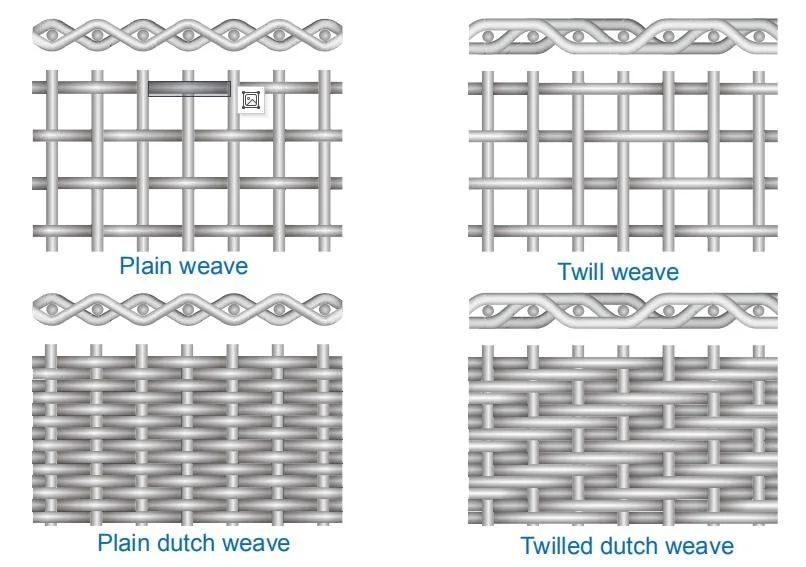

Kain tenun belanda kepar

Kain tenun Walanda Twill nggabungake tenun Walanda lan tenun kepar kanggo nyedhiyakake kain penyaring bolong sing apik.Kabel tutup dilewati lan ing sangisore rong kabel warp, nyedhiyakake panyaring sing ketat lan apik kanthi bukaan sing tirus.Proses tenun ngidini kanggo nggunakake kabel banget nggoleki, kanggo ukuran micron, prodhuksi nyaring bolong kanggo aplikasi gas lan Cairan.

Tabel ing ngisor iki nuduhake kelas lan spesifikasi standar sing kasedhiya kanggo Kain Kawat Tenun Walanda Twill

| Mesh/Inci (warp×weft) | Kawat Dia.lungsin × pakan (mm) | Ukuran normal (m) | Efektif area% | Bobot kg / sq.m | Ketebalan kain (mm) |

| 20×270 | 0.25×0.2 | 119 | 17.6 | 3.14 | 0.65 |

| 20×200 | 0.355×0.28 | 118 | 12.1 | 4.58 | 0.915 |

| 24×300 | 0.28×0.18 | 110 | 19.6 | 3.01 | 0.64 |

| 20×150 | 0.45×0.355 | 101 | 7.5 | 6.02 | 1.16 |

| 30×340 | 0.28×0.16 | 89 | 17.9 | 2.84 | 0.60 |

| 30×270 | 0.28×0.20 | 77 | 11.2 | 3.41 | 0.68 |

| 40×540 | 0.18×0.10 | 70 | 23.5 | 1.73 | 0.38 |

| 40×430 | 0.18×0.125 | 63 | 15.4 | 2.09 | 0.43 |

| 50×600 | 0.125×0.09 | 51 | 17.2 | 1.47 | 0.305 |

| 50×500 | 0.14×0.11 | 47 | 12 | 1.83 | 0.364 |

| 65×600 | 0.14×0.09 | 36 | 1.59 | 0.32 | |

| 70×600 | 0.14×0.09 | 31 | 10.1 | 1.61 | |

| 78×760 | 0.112×0.071 | 13.5 | 1.25 | 0.254 | |

| 78×680 | 0.112×0.08 | 29 | 10.3 | 1.37 | 0.272 |

| 80×680 | 0.112×0.08 | 28 | 9.8 | 1.38 | |

| 90×850 | 0.10×0.063 | 26 | 12.7 | 1.12 | 0.226 |

| 90×760 | 0.10×0.071 | 24 | 9.6 | 1.23 | 0.242 |

| 100×850 | 0.10×0.063 | 22 | 10 | 1.14 | 0.226 |

| 130×1500 | 0.063×0.036 | 21 | 18.6 | 0.64 | 0.135 |

| 100×760 | 0.10×0.071 | 20 | 7.4 | 1.25 | 0.242 |

| 130×1200 | 0,071×0,045 | 18 | 12 | 0.80 | 0.161 |

| 130×1100 | 0.071×0.05 | 17 | 9.4 | 0.87 | 0.171 |

| 150×1400 | 0.063×0.04 | 15 | 11.4 | 0.71 | 0.143 |

| 160×1500 | 0.063×0.036 | 12.4 | 0.67 | 0.135 | |

| 165×1500 | 0.063×0.036 | 14 | 11.4 | ||

| 174×1700 | 0.063×0.032 | 13 | 12.9 | 0.62 | 0.127 |

| 165×1400 | 0.063×0.04 | 8.8 | 0.73 | 0.143 | |

| 174×1400 | 0.063×0.04 | 11 | 7.4 | 0.74 | |

| 203×1600 | 0.05×0.032 | 10 | 9.3 | 0.58 | 0.114 |

| 216×1800 | 0,045 × 0,03 | 9.4 | 0.53 | 0.105 | |

| 203×1500 | 0.056×0.036 | 9 | 6.2 | 0.67 | 0.128 |

| 250×1900 | 0.04×0.028 | 8 | 7.8 | 0.51 | 0.096 |

| 250×1600 | 0.05×0.032 | 3.8 | 0.63 | 0.114 | |

| 285×2100 | 0.036×0.025 | 7 | 7.2 | 0.44 | 0.086 |

| 300×2100 | 0.036×0.025 | 6 | 6.0 | ||

| 317×2100 | 0.036×0.025 | 5 | 4.7 | ||

| 325×2300 | 0.036×0.024 | 4 | 4.2 | ||

| 363×2300 | 0.032×0.022 | 4.5 | 0.40 | 0,076 | |

| 400×2700 | 0.028×0.02 | 4.7 | 0.36 | 0,068 |

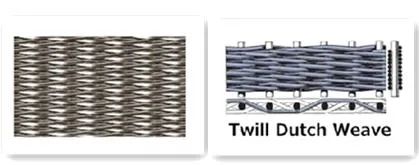

Kain Kawat Tenun Belanda Mundur & Kain Kawat Tenun Twill Belanda

Kain kawat tenunan Walanda mbalikke ditenun nganggo rong ukuran kawat.Kabel sing luwih cilik digunakake ing arah warp lan dirajut nganggo kabel shute sing luwih gedhe.Kabel sing luwih cilik dirajut kanthi rapet, nyedhiyakake bolong sing nyenyet kanggo nyaring.Kawat sing luwih gedhe menehi kekuatan kanggo bolong.Panggunaan utama kain kawat iki yaiku filtrasi lan pamisahan produk cair lan slurry.

Kain kawat tenunan Twill Walanda nggabungake tenun Walanda lan kepar kanggo nyedhiyakake kain penyaring bolong sing apik.Proses tenun ngidini nggunakake kabel sing apik banget, ngasilake bolong nyaring kanggo aplikasi gas lan cairan.Kita uga nyedhiyakake Herringbone lan Broken Pattern Reverse Twill Dutch Weave Products.

Tabel ing ngisor iki nuduhake kelas lan spesifikasi standar sing kasedhiya kanggo Kain Kawat Tenun Belanda Reverse & Kain Kawat Tenun Twill Walanda

| bolong | Diameter kawat (mm) | Akurasi nyaring |

| 63×18 | 0.30×0.4 | 200 |

| 107×20 | 0.24×0.4 | 150 |

| 175×44 | 0.15×0.30 | 80 |

| 132×32 | 0.20×0.40 | 105 |

| 290×70 | 0.09×0.20 | 55 |

| 615×102 | 0.04×0.16 | 40 |

| 720×140 | 0.035×0.11 | 15 |

| (Spesifikasi khusus kita bisa gawé miturut syarat customer) | ||

Parameter sing dibutuhake

a: materi

b: Diameter kawat

c: jaring

d: Cara Tenun: tenun polos, tenun kepar,

tenun belanda polos, tenun belanda kepar,

tenunan mundur, tenunan lima heddle

e: jembar

f: dawa

Kenapa milih Kita?

1. OEM kasedhiya;

2. Pengalaman produksi 8 taun nggawe kita luwih profesional ing lapangan Wire Mesh;

3. 6 mesin kanggo manufaktur, produksi luwih cepet lan wektu pangiriman cendhak;

4. Lulus sertifikat ISO9001, kualitas dhuwur bisa nggawe kabeh klien yakin.

Tim kita:

1. Wangsulan pitakon sampeyan sajrone 24 jam kerja;

2. pesenan pelanggan kasedhiya, OEM lan ODM disambut;

3. Kabeh barang sing dititi priksa dening QC profesional sadurunge pangiriman;

4. Pengiriman barang menyang pelanggan ing saindenging jagad kanthi cepet lan tepat;

5. Good after sales service, sembarang masalah produk bisa ditangani sakcepete;

6. Profesional & Integritas, partner setya lan long-term Panjenengan.

Pitakonan lan kunjungan sampeyan bakal disambut banget!