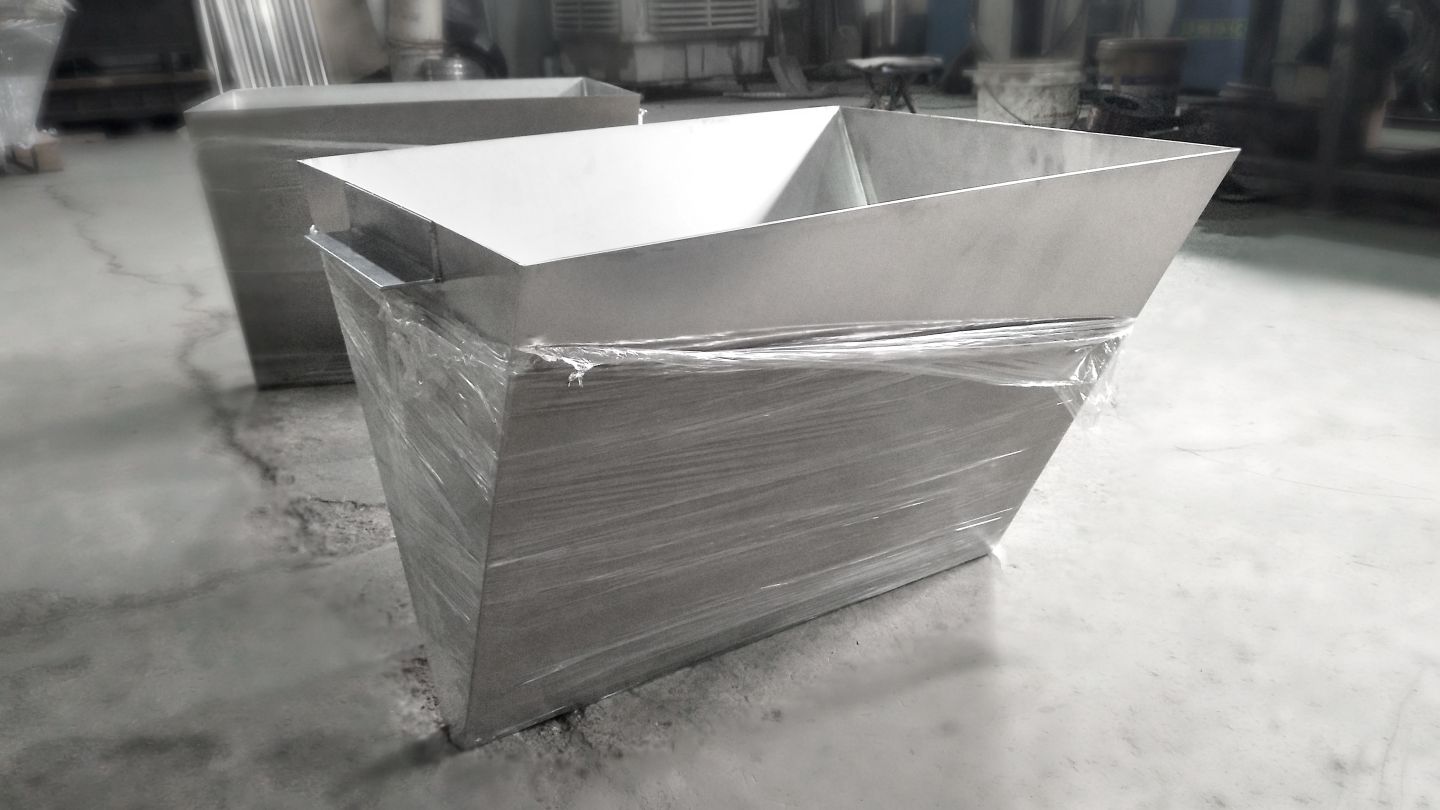

Customized CNC laser cutting parts and Weldment parts

Basic Info

Quick Details

|

Place of Origin |

China |

|

Model Number |

Customized |

|

Certification |

ISO9001:2015 |

|

Appliation |

Industry, Building, Municipal |

|

Specification |

According to customer's drawing or sample. |

|

Surface treatment |

Customized |

|

Min tolerance |

+/-0.5mm (According to Drawing) |

|

Samples |

We can make sample |

|

Shipping Port |

Xingang, Tianjin |

|

Delivery Time |

Subject to negotiation date |

|

Payment |

T/T 30 Days (30% Prepaid) |

Laser Cutting

Laser cutting is a process that uses a laser to cut different materials for both industrial and more artistic applications, such as etching.

Where is it Used?

Custom automated laser cutting is among the most effective processes for cutting plate or sheet metal for fabrication. This technology can be used for a variety of applications, including cutting and scribing metals such as aluminium, stainless steel, mild steel, titanium Steel and brass. However, the process can also be used for the industrial cutting of plastic, wood, ceramics, wax, fabrics, and paper.

Lasers are ideal for cutting metal as they provide clean cuts with a smooth finish. Laser cut metal can be widely found for components and structural shapes including car bodies, mobile phone cases, engine frames or panel beams.

No matter what metal your project needs, these sophisticated tools can cut it with a precise, high quality edge.

Precision • Efficiency • Flexibility • Low Cost

The Advantages

● Reduced contamination

● Easier workholding

● Precision can see improvements

● Materials are less prone to warping

● High levels of precision and accuracy

● Less wastage

● Lower energy use

● Lower costs

Welding

Welding is a fabrication process that lets you join materials like metals by using heat at high temperatures. After cooling the base metal and the filler metal get attached. Welding uses high temperature to join the materials, whereas the process like soldering and brazing do not let the base metal to melt.

Welding is a fabrication process that lets you join materials like metals by using heat at high temperatures. After cooling the base metal and the filler metal get attached. Welding uses high temperature to join the materials, whereas the process like soldering and brazing do not let the base metal to melt.

Types of Welding

From gas flame to ultrasound, there are many energies used in welding like electron beams, electric arc, LASER, and friction. There are many types of welding used for various purposes under different situations. They are:

Manual welding includes:

● Forge welding

● Arc welding

● Oxy-fuel welding

● Shielded metal arc welding

● Gas metal arc welding

● Submerged arc welding

● Flux-cored arc welding

● Electroslag welding

● Laser beam welding

● Electron beam welding

● Magnetic pulse welding

● Friction stir welding

● Forge Welding

The Advantages

● Strong, durable, and permanent

● Easier workholding

● Simple operation

● Stronger weld than the base material

● Be performed at any place

● Economical and affordable

● Widely used

Product Description

|

Process |

Laser Cutting & Weldment |

|

Material |

Stainless Steel, Carbon Steel, Mild Steel, Aluminum, Iron, Copper |

|

Surface treatment |

- Passivation - Polishing - Sand blasting - Electroplating(color, blue, white, black zinc, Ni, Cr, tin, copper, silver) - Hot-dip galvanizing - Black oxide coating - Spray-Paint - Rust preventive oil |

|

Processing Ability |

Size tolerance: +/-0.5mm or Accroding to drawings |

|

Application |

Our products are widely used in Industrial , Building & Municipal. Such as automobile, truck, train, railway, fitness equipment, agricultural machinery, mining machinery, petroleum machinery, engineering machinery, shipbuilding, construction and other power equipment.

Mechanical Components/parts Boat parts and Marine hardware Construction hardware Auto parts and accessories Medical Instrument parts |

|

Design |

Pro/E, Auto CAD, Solid work, CAXA UG, CAM, CAE. Various type of 2D or 3D drawings are acceptable,such as JPG, PDF, DWG, DXF, IGS, STP, X_T, SLDPRT etc. |

|

Standards |

AISI, ATSM, UNI, BS, DIN, JIS, GB etc. Or Non standard customization. |

|

Inspection |

Dimension inspection Finish inspection Material inspection - ( Inspection on critical dimensions or follow your special requst. ) |

|

Certification |

ISO9001:2015 quality management system certificate. ( Continuous update ) |

100% Quality, 100% Delivery

We take pride in constantly improving our customer experience, technology, and support. We work closely with our customers in order to provide the highest level of service.

We combine our vast knowledge and expertise with state-of-the-art equipment and software to produce work quickly, efficiently, and at competitive prices. We constantly review and improve our procedures for better results.

Factory