Likarolo tse ikhethileng tsa CNC laser ho itšeha le likarolo tsa Weldment

Lintlha tsa Motheo

Lintlha tse Potlakileng

| Sebaka sa Tšimoloho | China |

| Nomoro ea Mohlala | Customized |

| Setifikeiti | ISO9001:2015 |

| Tshebediso | Indasteri, Moaho, Masepala |

| Tlhaloso | Ho latela setšoantšo sa moreki kapa sampole. |

| Phekolo ea bokaholimo | Customized |

| Mamello e nyane | +/-0.5mm (Ho ea ka Motako) |

| Mehlala | Re ka etsa mohlala |

| Boema-kepe ba Likepe | Xingang, Tianjin |

| Nako ea thomello | Ho latela letsatsi la lipuisano |

| Tefo | T/T Matsatsi a 30 (30% Prepaid) |

Ho khaola Laser

Ho itšeha ka laser ke mokhoa o sebelisang laser ho khaola lisebelisoa tse fapaneng bakeng sa lits'ebetso tsa indasteri le tsa bonono, joalo ka etching.

E sebelisoa Hokae?

Custom automated laser cutting ke e 'ngoe ea mekhoa e atlehang ka ho fetisisa ea ho seha poleiti kapa lakane ea tšepe bakeng sa ho etsoa.Theknoloji ena e ka sebelisoa bakeng sa lits'ebetso tse fapaneng, tse kenyelletsang ho seha le ho ngola litšepe tse kang aluminium, tšepe e sa hloekang, tšepe e bonolo, titanium Steel le koporo.Leha ho le joalo, mokhoa ona o ka boela oa sebelisoa bakeng sa ho seha liindasteri tsa polasetiki, lehong, lirafshoa, boka, masela le pampiri.

Li-laser li loketse ho seha tšepe kaha li fana ka likhahla tse hloekileng tse nang le qetello e boreleli.Litšepe tse sehiloeng tsa laser li ka fumaneha ka bongata bakeng sa likarolo le libopeho tsa sebopeho ho kenyelletsa 'mele ea koloi, likheche tsa mehala ea mehala, liforeimi tsa enjine kapa maballo a phanele.

Ho sa tsotellehe hore na morero oa hau o hloka tšepe efe, lisebelisoa tsena tse rarahaneng li ka li khaola ka mokhoa o nepahetseng, oa boleng bo phahameng.

Ho nepahala • Ho sebetsa hantle • Ho fetoha le maemo • Theko e tlaase

Melemo

● Ho fokotsa tšoaetso

● Ho sebetsa habonolo

● Ho nepahala ho ka bona lintlafatso

● Thepa ha e sothe hakaalo

● Boemo bo phahameng ba ho nepahala le ho nepahala

● Tšenyo e fokolang

● Tšebeliso e tlaase ea matla

● Litšenyehelo tse tlaase

Welding

Welding ke mokhoa oa ho etsa lintho o u lumellang hore u kopanye lisebelisoa tse kang tšepe ka ho sebelisa mocheso mochesong o phahameng.Ka mor'a ho pholile tšepe ea motheo le tšepe ea ho tlatsa li kenngoa.Welding e sebelisa mocheso o phahameng ho kopanya lisebelisoa, athe ts'ebetso e joalo ka soldering le brazing e sa lumelle tšepe ea motheo ho qhibiliha.

Welding ke mokhoa oa ho etsa lintho o u lumellang hore u kopanye lisebelisoa tse kang tšepe ka ho sebelisa mocheso mochesong o phahameng.Ka mor'a ho pholile tšepe ea motheo le tšepe ea ho tlatsa li kenngoa.Welding e sebelisa mocheso o phahameng ho kopanya lisebelisoa, athe ts'ebetso e joalo ka soldering le brazing e sa lumelle tšepe ea motheo ho qhibiliha.

Mefuta ea Welding

Ho tloha lelakabe la khase ho isa ho ultrasound, ho na le matla a mangata a sebelisoang ho cheselletsa joalo ka maballo a elektrone, arc ea motlakase, LASER le likhohlano.Ho na le mefuta e mengata ea li-welding tse sebelisetsoang merero e fapaneng tlas'a maemo a fapaneng.Ke:

Welding ka letsoho e kenyelletsa:

● Forge welding

● Ho cheseletsa arc

● Oxy-fuel welding

● Tšhelete ea tšepe e sirelelitsoeng

● Ho cheseletsa arc ea tšepe ea khase

● Ho tjheseletsa arc ka metsing

● Flux-cored arc welding

● Electroslag welding

● Ho tjheseletsa beam ka laser

● Ho tjheseletsa maballo a elektrone

● Magnetic pulse welding

● tšubuhlellano ea likhohlano e sisinyeha

● Forge Welding

Melemo

● E matla, e tšoarella, ebile e tšoarella

● Ho sebetsa habonolo

● Tšebetso e bonolo

● Weld e matla ho feta thepa ea motheo

● E etsetsoa sebakeng leha e le sefe

● E na le chelete e ngata ebile e theko e tlaase

● E sebelisoa haholo

Tlhaloso ea Sehlahisoa

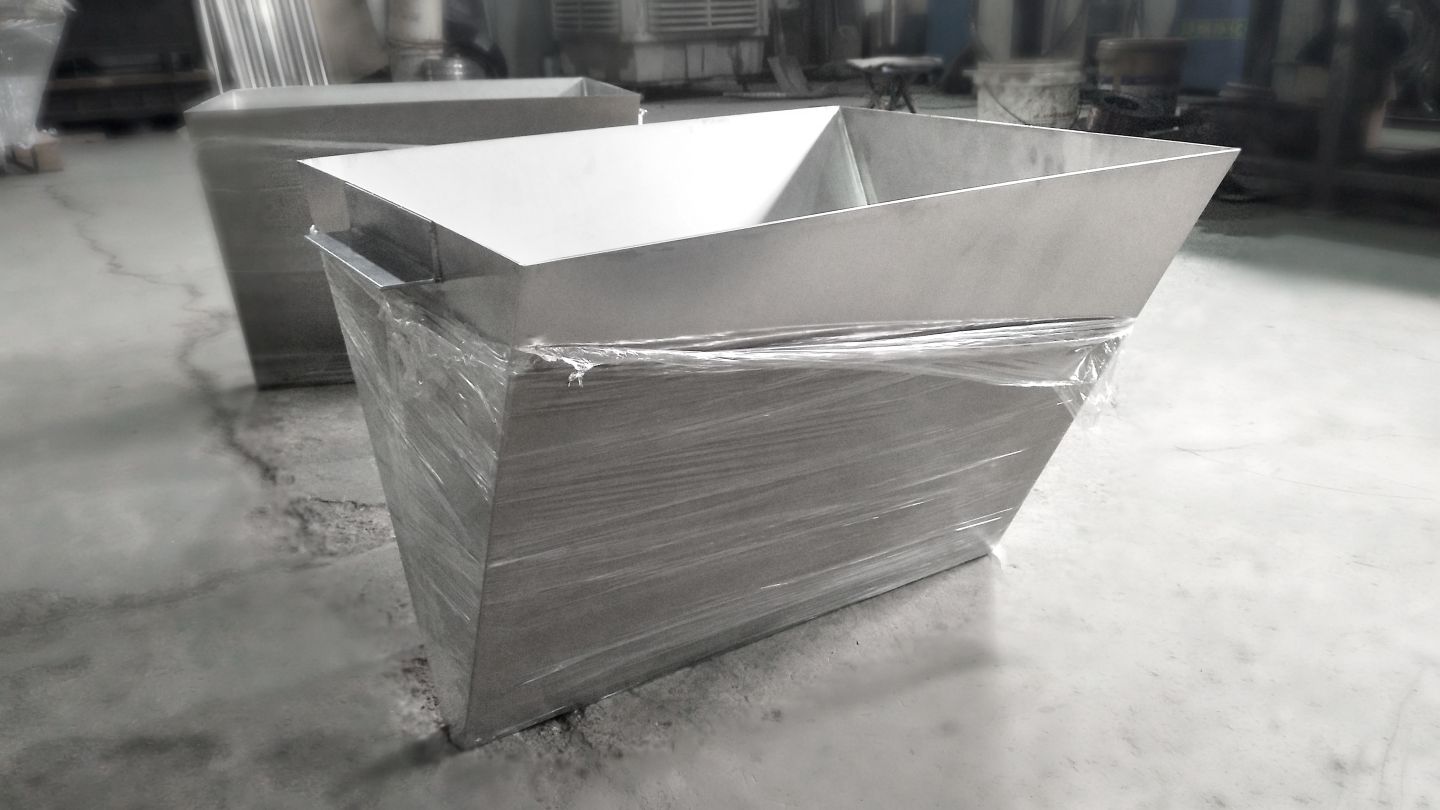

| Tshebetso | Laser Cutting & Weldment |

| Lintho tse bonahalang | Tšepe e se nang tšepe, tšepe ea carbon, tšepe e bonolo, aluminium, tšepe, koporo |

| Phekolo ea bokaholimo | - Phahamiso - Ho benya - Ho phatloha ha lehlabathe - Electroplating ('mala, o moputsoa, o mosoeu, zinki e ntšo, Ni, Cr, tin, koporo, silevera) - Ho qoela ka galvanizing e chesang - Ho roala ha oxide e ntšo - Spray-Pente - Oli e thibelang mafome |

| Bokhoni ba Ts'ebetso | Mamello ea boholo: +/- 0.5mm kapa Acroding ho litšoantšo |

| Kopo | Lihlahisoa tsa rona li sebelisoa haholo indastering, Building & Municipal.Tse kang koloi, teraka, terene, terene, lisebelisoa tsa boikoetliso, mechine ea temo, mechine ea merafo, mechine ea peterole, mechine ea boenjiniere, kaho ea likepe, kaho le lisebelisoa tse ling tsa matla.

Mechine / likarolo Likarolo tsa likepe le lisebelisoa tsa Marine Lisebelisoa tsa kaho Likarolo tsa Auto le lisebelisoa Likarolo tsa lisebelisoa tsa bongaka |

| Moralo | Pro/E, Auto CAD, Mosebetsi o tiileng, CAXA UG, CAM, CAE. Mefuta e fapaneng ea litšoantšo tsa 2D kapa 3D lia amoheleha, joalo ka JPG, PDF, DWG, DXF, IGS, STP, X_T, SLDPRT jj. |

| Litekanyetso | AISI, ATSM, UNI, BS, DIN, JIS, GB joalo-joalo. Kapa Non standard customization. |

| Tlhahlobo | Tlhahlobo ea tekanyo Qetella ho hlahloba Tlhahlobo ea thepa - (Hlahloba litekanyo tsa bohlokoa kapa u latele kopo ea hau e khethehileng.) |

| Setifikeiti | ISO9001: Setifikeiti sa tsamaiso ea boleng ba 2015. (Nchafatso e tsoelang pele) |

100% Quality, 100% Delivery

Re motlotlo ho lula re ntlafatsa boiphihlelo ba bareki, theknoloji le tšehetso.Re sebetsa haufi-ufi le bareki ba rona e le hore re fane ka litšebeletso tse phahameng ka ho fetisisa.

Re kopanya tsebo ea rona e kholo le boitseanape le lisebelisoa tsa morao-rao le software ho hlahisa mosebetsi ka potlako, ka bokhabane, le ka litheko tsa tlholisano.Re lula re hlahloba le ho ntlafatsa mekhoa ea rona bakeng sa liphetho tse ntle.

Feme