Iinxalenye zeCNC zokusika ezenziwe ngokwezifiso kunye neenxalenye zeWeldment

Ulwazi olusisiseko

Iinkcukacha eziKhawulezayo

| Indawo yeMvelaphi | eTshayina |

| Inombolo yoMfanekiso | Customized |

| Isiqinisekiso | ISO9001:2015 |

| Usetyenziso | Ishishini, iSakhiwo, uMasipala |

| Inkcazo | Ngokomzobo womthengi okanye isampuli. |

| Unyango lomphezulu | Customized |

| Ukunyamezelana okuncinci | +/-0.5mm (NgokoMzobo) |

| Iisampulu | Singenza isampuli |

| Izibuko zokuHamba | Xingang, Tianjin |

| Ixesha lokuzisa | Kuxhomekeke kumhla wothethathethwano |

| Intlawulo | T/T Iintsuku ezingama-30 (30% ehlawulwa kwangaphambili) |

Ukusika iLaser

Ukusika kweLaser yinkqubo esebenzisa i-laser ukusika izinto ezahlukeneyo kuzo zombini ushishino kunye nezicelo zobugcisa, ezinje nge-etching.

Isetyenziswa phi?

Ukusika i-laser ngokuzenzekelayo kuphakathi kwezona nkqubo zisebenzayo zokusika ipleyiti okanye isinyithi seshiti ukuze kwenziwe.Le teknoloji ingasetyenziselwa usetyenziso oluhlukeneyo, kubandakanywa ukusika kunye nokubhala isinyithi ezifana ne-aluminium, insimbi engenasici, insimbi epholileyo, i-titanium Steel kunye nobhedu.Nangona kunjalo, inkqubo inokusetyenziselwa ukusika iplastiki, iinkuni, iiseramiki, iwax, amalaphu kunye nephepha.

I-Lasers ilungele ukusika isinyithi njengoko ibonelela ngokucokisekileyo ngokucokisekileyo.I-Laser cut metal inokufunyanwa ngokubanzi kumacandelo kunye neemilo zesakhiwo kubandakanya imizimba yemoto, iimeko zefowuni ephathwayo, iifreyimu ze-injini okanye imiqadi yephaneli.

Kungakhathaliseki ukuba yiyiphi isinyithi efunwa yiprojekthi yakho, ezi zixhobo ziyinkimbinkimbi zinokuyisika ngomgca ochanekileyo, ophezulu.

Ukuchaneka • Ukusebenza kakuhle • Ukuguquguquka • Iindleko eziphantsi

Iingenelo

● Usulelo olucuthiweyo

● Ukusebenza lula

● Ukuchaneka kunokubona uphuculo

● Izinto eziphathekayo azithandeki kangako ekujikeni

● Amanqanaba aphezulu okuchaneka nokuchaneka

● Inkcitho encinci

● Ukusetyenziswa kwamandla asezantsi

● Iindleko eziphantsi

Ukuwelda

Ukuwelda yinkqubo yokwenziwa ekuvumela ukuba udibanise imathiriyeli efana neentsimbi ngokusebenzisa ubushushu kumaqondo obushushu aphezulu.Emva kokupholisa isiseko sesinyithi kunye nentsimbi yokuzalisa iqhotyoshelwe.I-Welding isebenzisa ubushushu obuphezulu ukujoyina izixhobo, ngelixa inkqubo efana ne-soldering kunye ne-brazing ingavumeli ukuba isiseko sesinyithi sinyibilike.

Ukuwelda yinkqubo yokwenziwa ekuvumela ukuba udibanise imathiriyeli efana neentsimbi ngokusebenzisa ubushushu kumaqondo obushushu aphezulu.Emva kokupholisa isiseko sesinyithi kunye nentsimbi yokuzalisa iqhotyoshelwe.I-Welding isebenzisa ubushushu obuphezulu ukujoyina izixhobo, ngelixa inkqubo efana ne-soldering kunye ne-brazing ingavumeli ukuba isiseko sesinyithi sinyibilike.

Iintlobo zeWelding

Ukusuka kwidangatye legesi ukuya kwi-ultrasound, maninzi amandla asetyenziswa ukuwelda njengemiqadi ye-electron, i-arc yombane, i-LASER, kunye nokukhuhlana.Kukho iintlobo ezininzi ze-welding ezisetyenziselwa iinjongo ezahlukeneyo phantsi kweemeko ezahlukeneyo.Bazi:

Ukuwelda ngesandla kubandakanya:

● Forge welding

● i-arc welding

● I-oxy-fuel welding

● I-arc yentsimbi ekhuselweyo

● Igesi yentsimbi ye-arc welding

● i-arc efakwe emanzini

● i-Flux-cored arc welding

● Electroslag welding

● Laser beam welding

● Ukuwelda ngomqa we-electron

● I-Magnetic pulse welding

● I-welding ye-friction

● Forge Welding

Iingenelo

● Yomelele, yomelele kwaye isisigxina

● Ukusebenza lula

● Ukusebenza okulula

● I-weld enamandla kunesiseko sezinto

● Yenziwa nakweyiphi na indawo

● Uqoqosho kwaye luyafikeleleka

● Isetyenziswa ngokubanzi

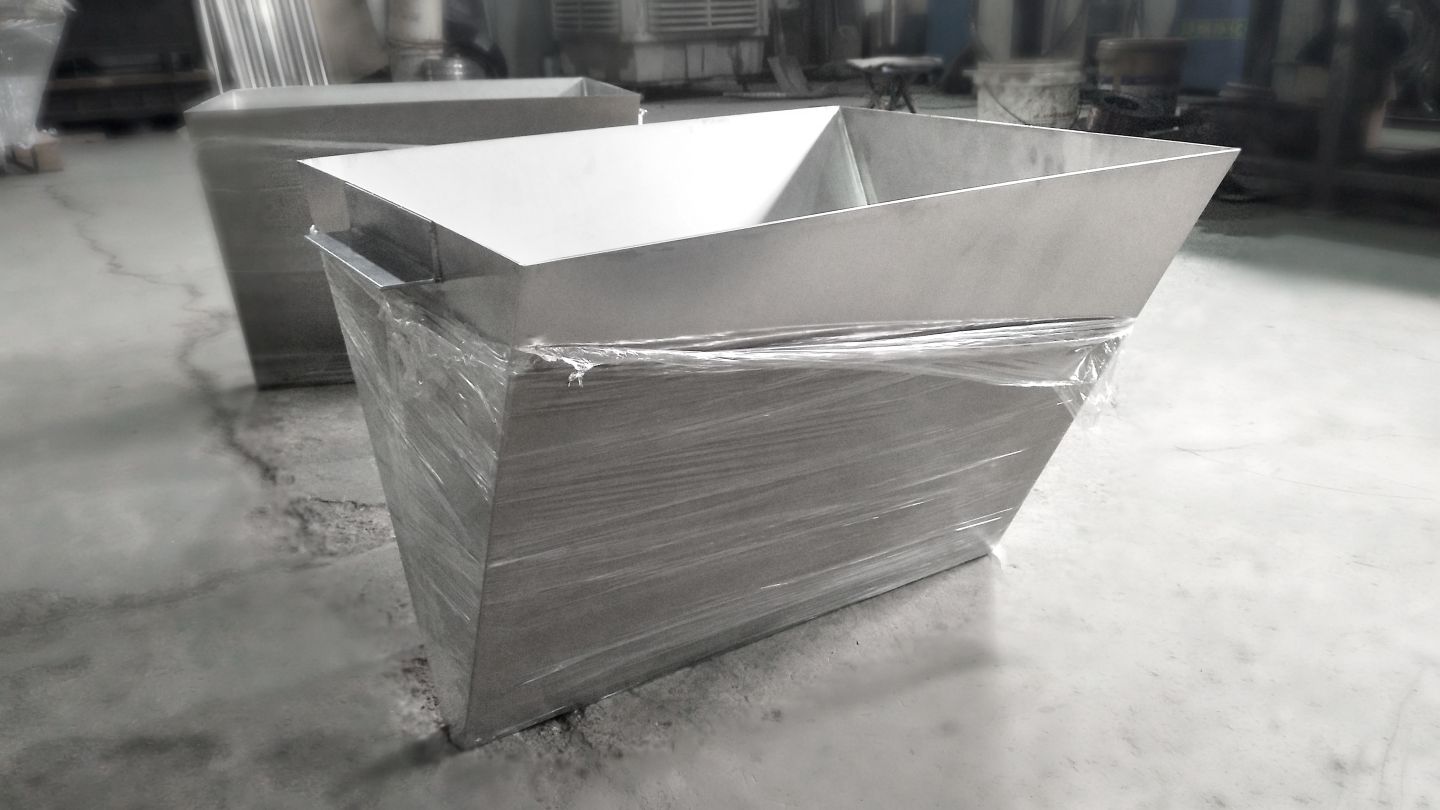

Ingcaciso yeMveliso

| Inkqubo | Laser Cutting & Weldment |

| Izinto eziphathekayo | Intsimbi yeStainless, iCarbon Steel, iMild Steel, iAluminiyam, intsimbi, ubhedu |

| Unyango lomphezulu | - Ukunyusa - Ukugudisa - Ukuqhushumba kwesanti -Electroplating (umbala, blue, mhlophe, zinc emnyama, Ni, Cr, tin, ubhedu, isilivere) -Hot-dip galvanizing - Ukwaleka oxide emnyama - Ukutshiza-Ipeyinti - Ioli yokuthintela umhlwa |

| Amandla okuqhuba | Ukunyamezela ubungakanani: +/- 0.5mm okanye Ukungena kwimizobo |

| Isicelo | Iimveliso zethu zisetyenziswa kakhulu kwi-Industrial, Building & kaMasipala.Njengemoto, iilori, uloliwe, uloliwe, izixhobo zokufaneleka, oomatshini bezolimo, oomatshini bemigodi, oomatshini bepetroleum, oomatshini bobunjineli, ukwakha iinqanawa, ukwakhiwa kunye nezinye izixhobo zamandla.

Amacandelo oomatshini/amacandelo Iinxalenye zesikhephe kunye nezixhobo zaseLwandle Izixhobo zokwakha Amalungu Auto kunye nezincedisi Amalungu esixhobo soNyango |

| Yila | I-Pro / E, i-Auto CAD, umsebenzi oqinileyo, i-CAXA UG, i-CAM, i-CAE. Iindidi ezahlukeneyo zemizobo ye-2D okanye ye-3D yamkelekile, enje ngeJPG, PDF, DWG, DXF, IGS, STP, X_T, SLDPRT njl. |

| Imigangatho | AISI, ATSM, UNI, BS, DIN, JIS, GB njl. Okanye Non standard customization. |

| Ukuhlolwa | Ukuhlolwa komgangatho Gqibezela ukuhlola Ukuhlolwa kwezinto - (Ukuhlolwa kwemilinganiselo ebalulekileyo okanye ulandele isicelo sakho esikhethekileyo.) |

| Isiqinisekiso | ISO9001: Isiqinisekiso senkqubo yolawulo lwe-2015. (Uhlaziyo oluqhubekayo) |

100% Umgangatho, 100% Ukuhanjiswa

Siyazingca ngokusoloko siphucula amava ethu abathengi, itekhnoloji kunye nenkxaso.Sisebenza ngokusondeleyo nabathengi bethu ukuze sinikeze inqanaba eliphezulu lenkonzo.

Sidibanisa ulwazi lwethu oluninzi kunye nobuchule kunye nezixhobo zanamhlanje kunye nesofthiwe yokuvelisa umsebenzi ngokukhawuleza, ngokufanelekileyo, kunye namaxabiso akhuphisanayo.Sihlala sivavanya kwaye siphucula iinkqubo zethu ukufumana iziphumo ezingcono.

Umzi-mveliso